DM KEM 70 Cement Injection Machine With Double Boiler

.jpeg)

The DM - KEM 70 is a high-performance cement injection machine equipped with double boilers, designed for pumping high-density, low-viscosity liquid calcium-based materials such as cement, plaster mixtures, stucco, and grout — whether in vertical or horizontal applications, and at high pressures.

Ideal for repair, stabilization, and reinforcement projects on structures like bridges, buildings, and dams, the KEM 70 also excels in anchorage filling, cement flooring, grouting, vertical or upward pumping of cement and lime-based solutions, clay transfer, tunneling, and precast unit production.

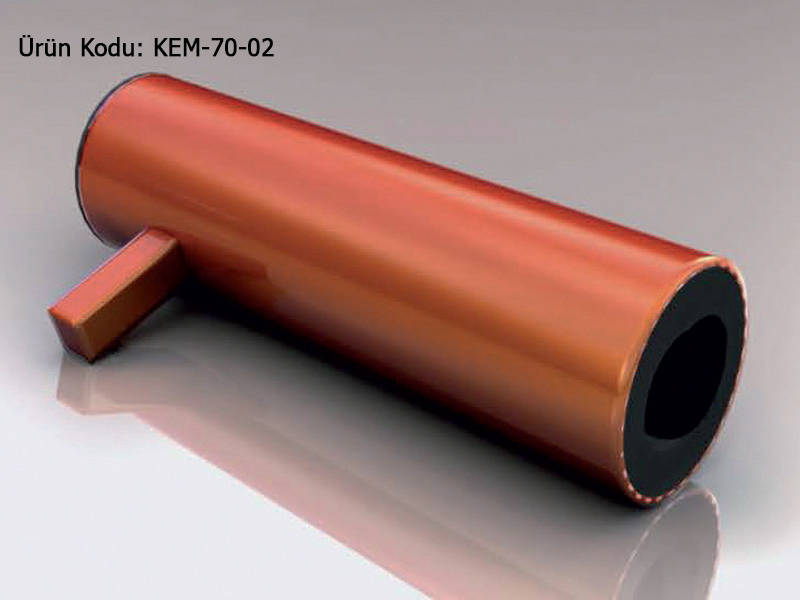

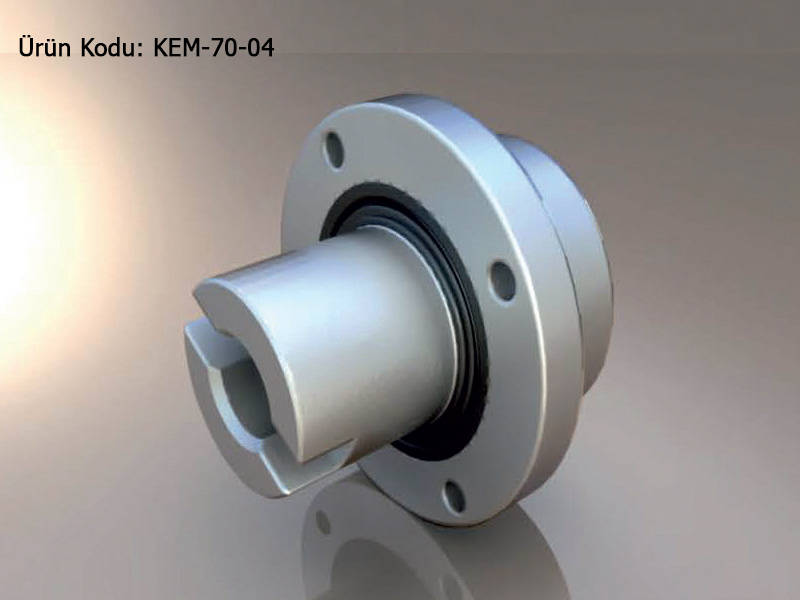

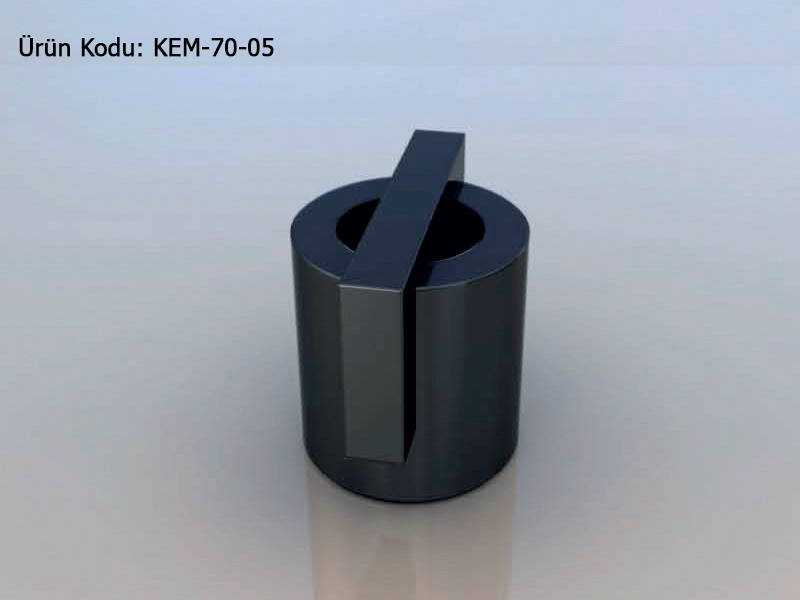

Its integrated mixer and water intake section ensure easy preparation of mixtures at precise ratios. The prepared mixture is transported via a hose, with interchangeable nozzles to suit different application needs. All mixture-contact parts are corrosion-resistant and can be washed after use.

Safety is paramount — a sealed, dust- and water-resistant electrical panel protects the operator, supported by features like phase sequence protection, voltage fluctuation control, thermal overload protection, and more.

Thanks to its compact design, the KEM 70 operates comfortably even in tight or low-ceiling environments. Spare part replacement is simple and doesn’t require expert technicians or calibration. With durable, cost-effective parts, the DM - KEM 70 is an essential addition to any construction equipment fleet.

- Dimensions: 300 × 90 × 165 cm

- Gross Weight: 580 kg

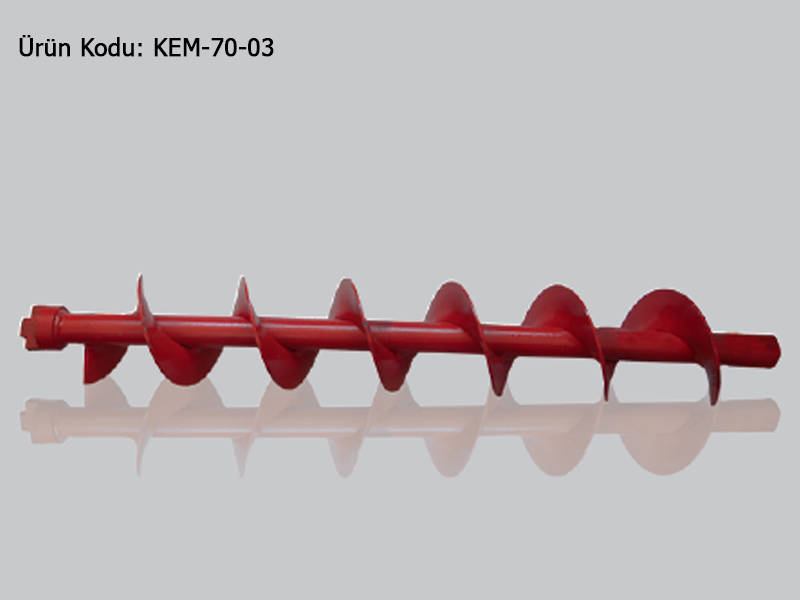

- Rotor Type: P8

- Theoretical Pumping Capacity: 70 lt/min

- Maximum Output Pressure: 40 bar

- Output Hose Diameter: 1 inch

- Max. Pumping Range (Vertical): 80 m

- Max. Pumping Range (Horizontal): 100 m

- Main Motor Power: 7.5 kW

- Mixer Motor Power: 3 × 2 kW

- Voltage / Frequency: 380 V / 50 Hz

- Total Consumption: 13.5 kW

- Rotor Speed: 407 rpm

- Mixer Speed: 55 rpm

- Boiler Volume: 200 × 2 litres

Photo Gallery

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)