DM-KEM 40 Cement Injection Machine with Boiler

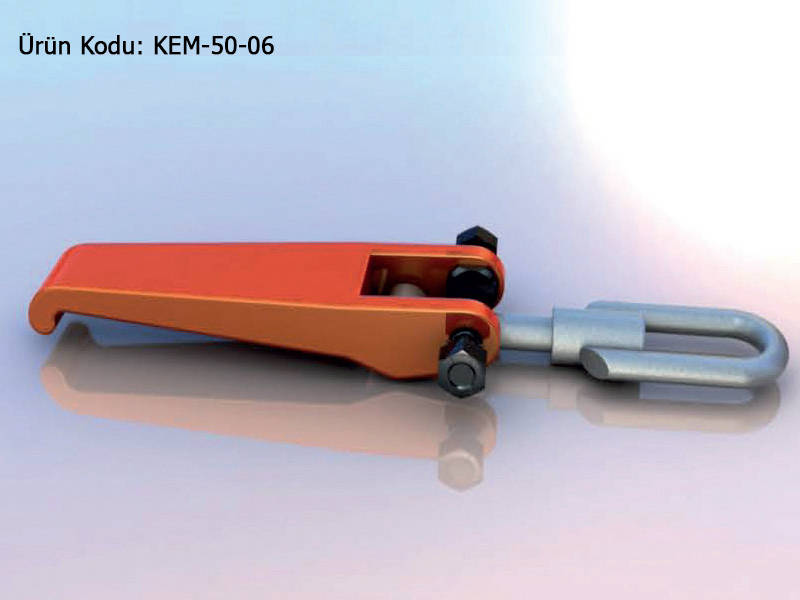

The DM-KEM 40 is a machine used for injection pumping liquid calcium-based chemicals with high density and low viscosity, such as cement, plaster mixtures, stucco, and grout, at high pressures in vertical and horizontal positions. It is an excellent solution for the repair, stabilization, and strengthening of structures like bridges, buildings, and dams; as well as for operations such as anchorage filling, cement flooring, grouting, and pumping cement, plaster, lime, or other solutions to construction areas. With its integral mixer and water intake section, the mixture can be easily prepared in desired proportions. The mixture in the boiler is transferred to the operation area via a hose; and according to customer needs, the hose nozzles can be easily changed. All parts in contact with the mixture are washable and corrosion-resistant. The double-sealed, water and dust-resistant electrical panel ensures operator safety. Safety features include phase sequence protection, high and low voltage protection, leakage current protection, overcurrent protection, and thermal protection. Spare part replacement is straightforward and does not require calibration. Its compact design allows use in confined spaces and low-ceilinged areas. With high-quality spare parts at affordable prices, the DM-KEM 40 is an indispensable piece of equipment for your machinery fleet.

- Technical Specifications

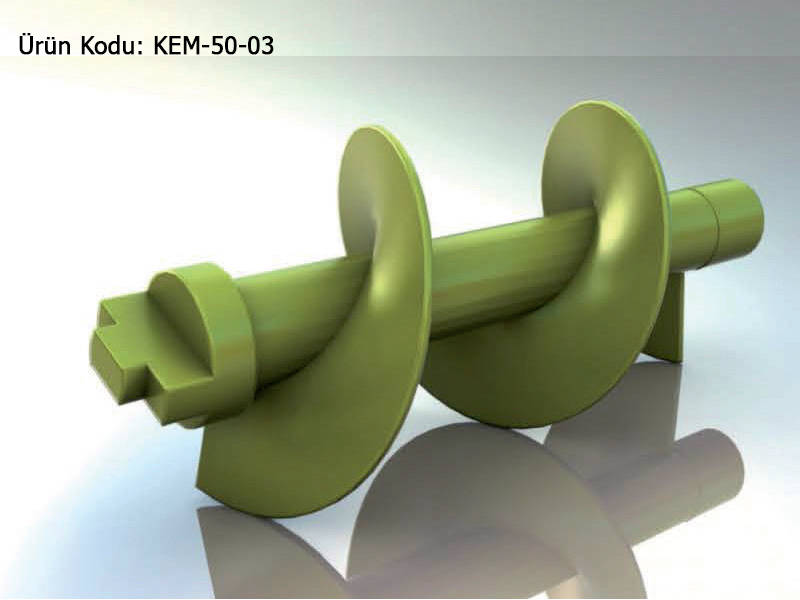

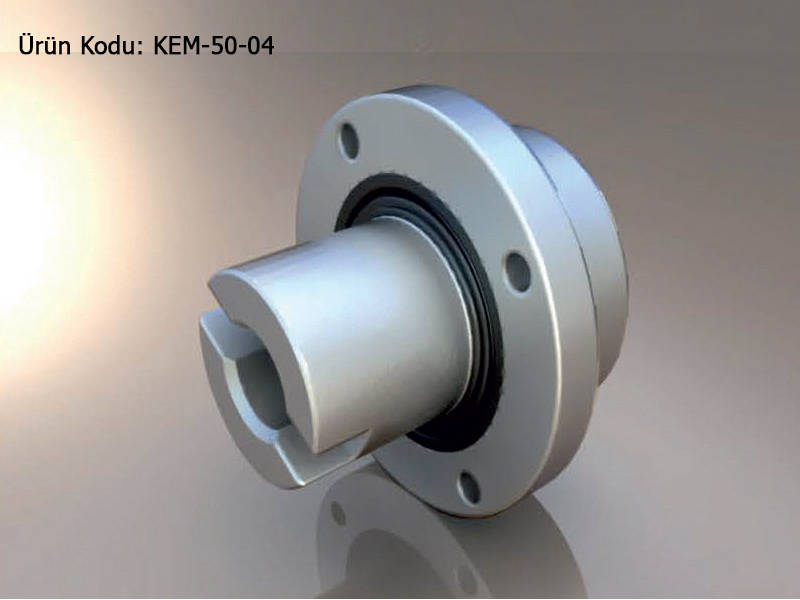

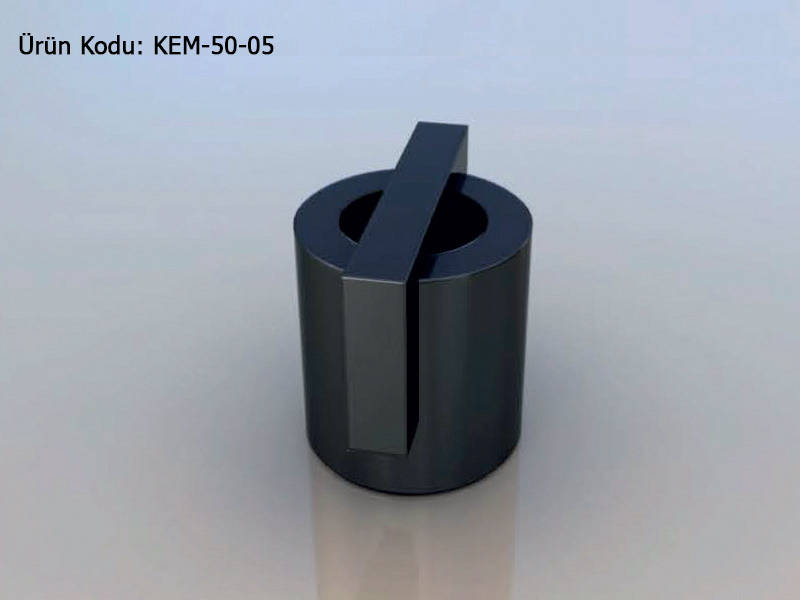

Specification Value Dimensions 240 × 110 × 170 cm Gross Weight 450 kg Rotor Type P8 Theoretical Pumping Capacity 70 L/min Maximum Output Pressure 40 bar Outlet Hose Diameter 1 inch Maximum Delivery Distance (Vertical) 80 m Maximum Delivery Distance (Horizontal) 100 m Main Motor Power 7.5 kW Mixer Motor Power 3 kW Voltage / Frequency 380 V / 50 Hz Total Power Consumption 10.5 kW Rotor Speed 407 rpm Mixer Speed 55 rpm Tank Capacity 400 liters

Photo Gallery