DM-KEM 20 Cement Injection Machine with Boiler

The DM-KEM 20 is a high-performance cement injection machine with an integrated boiler, engineered for injecting calcium-based liquid materials such as cement, plaster, grout, and stucco. It handles high-density, low-viscosity mixtures at high pressure for both vertical and horizontal applications.

It is an ideal solution for the repair, stabilization, and structural reinforcement of buildings, bridges, dams, and similar infrastructure. The machine also excels in applications such as anchorage filling, floor screeding, grout injection, upward or directional material pumping, clay transfer, tunnel operations, and precast concrete production.

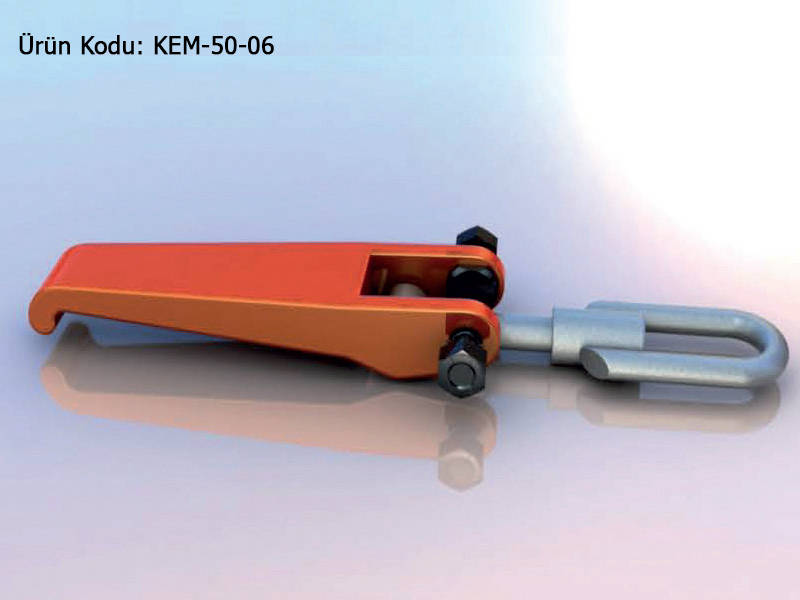

Thanks to its integrated mixer and water intake system, users can easily prepare mixtures in precise ratios. The material is delivered through a hose to the application point, and the nozzle can be quickly changed based on project requirements.

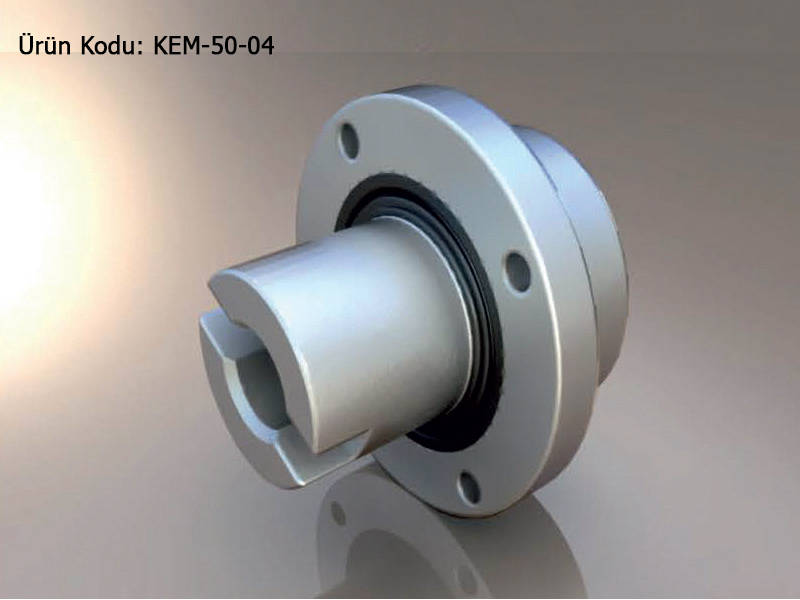

All contact components are corrosion-resistant and washable, ensuring long-term durability. The dual-sealed, dust- and waterproof electrical panel guarantees operator safety, supported by advanced safety features like phase sequence control, voltage protection, overcurrent, and thermal protection.

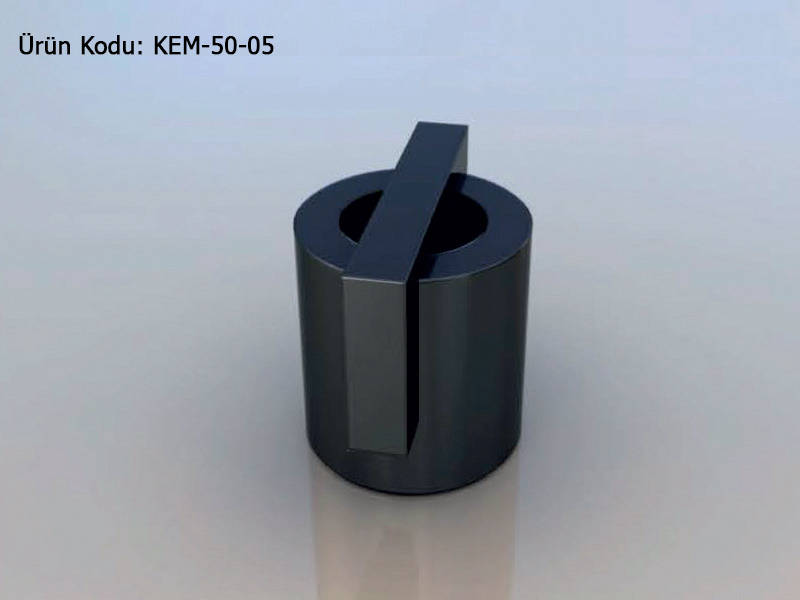

With easy maintenance, no calibration required, and tool-free spare part replacement, the DM-KEM 20 is user-friendly and highly reliable. Its compact structure makes it perfect for narrow or low-clearance spaces.

Durable, efficient, and cost-effective—DM-KEM 20 is a valuable asset for any construction equipment fleet.

Dimensions: 250 × 110 × 160 cm

Gross Weight: 380 kg

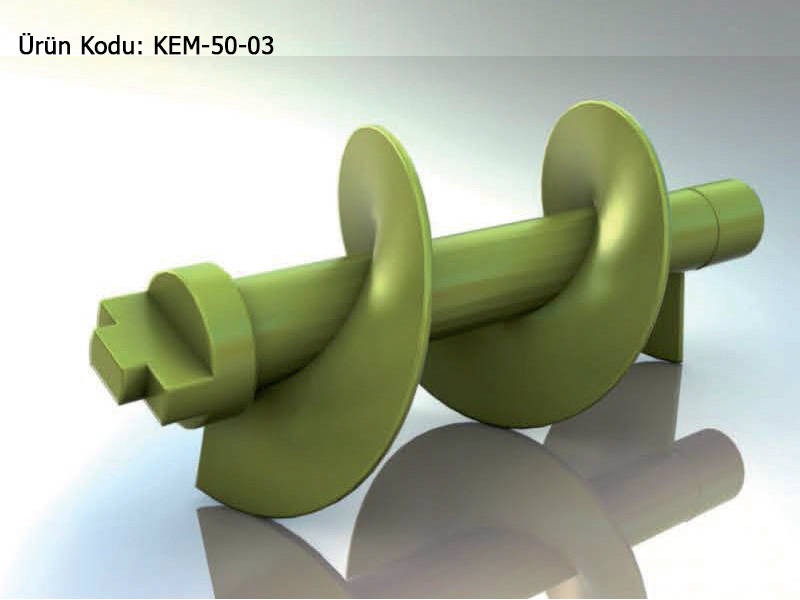

Rotor Type: P8

Theoretical Pumping Capacity: 50 lt/min

Maximum Output Pressure: 15 bar

Output Hose Diameter: 1 inch

Max. Pumping Range (Vertical): 30 m

Max. Pumping Range (Horizontal): 60 m

Main Motor Power: 5.5 kW

Mixer Motor Power: 3 kW

Voltage / Frequency: 380 V / 50 Hz

Total Consumption: 8.5 kW

Rotor Speed: 277 rpm

Mixer Speed: 55 rpm

Boiler Volume: 250 litres

Photo Gallery