Cement Injection Machine With Boiler DM-KEM 30

The DM-KEM 30 Cement Injection Machine with Boiler is designed for high-pressure injection of liquid calcium-based materials with high density and low viscosity, such as cement, plaster, stucco, and grout, in both vertical and horizontal applications.

This machine is an ideal solution for structural repair, stabilization, and reinforcement of bridges, buildings, and dams. It is also highly effective in anchorage filling, cement screeding, grouting, material pumping (cement, plaster, lime), clay transfer, tunnel works, and precast element production.

With its integrated mixer and water intake system, it enables precise preparation of the mixture to the desired ratios. The mixed material is transported to the application site via a hose, and the hose nozzles can be easily swapped based on project requirements.

All parts in contact with the mixture are corrosion-resistant and easy to clean. The electrical panel is double-sealed and water- and dust-resistant, ensuring maximum operator safety in demanding site conditions. Safety features include phase sequence protection, voltage fluctuation protection, overcurrent and thermal protection.

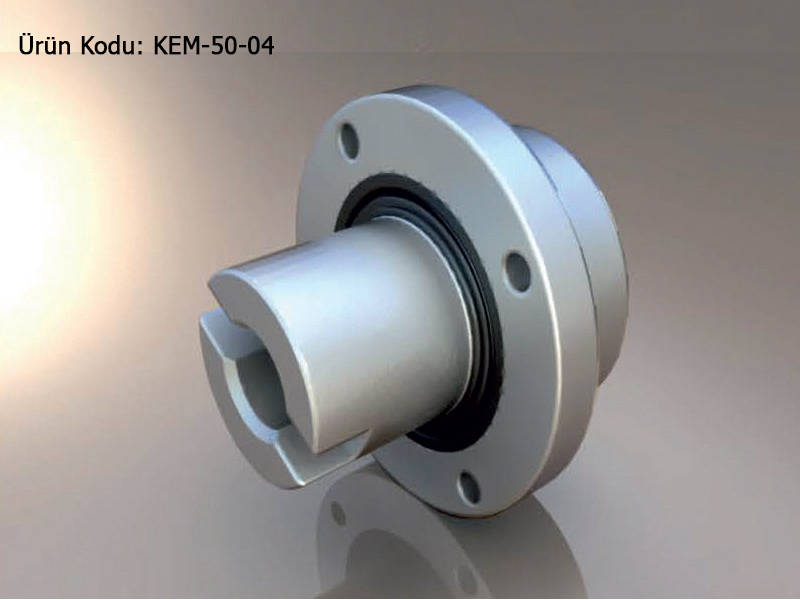

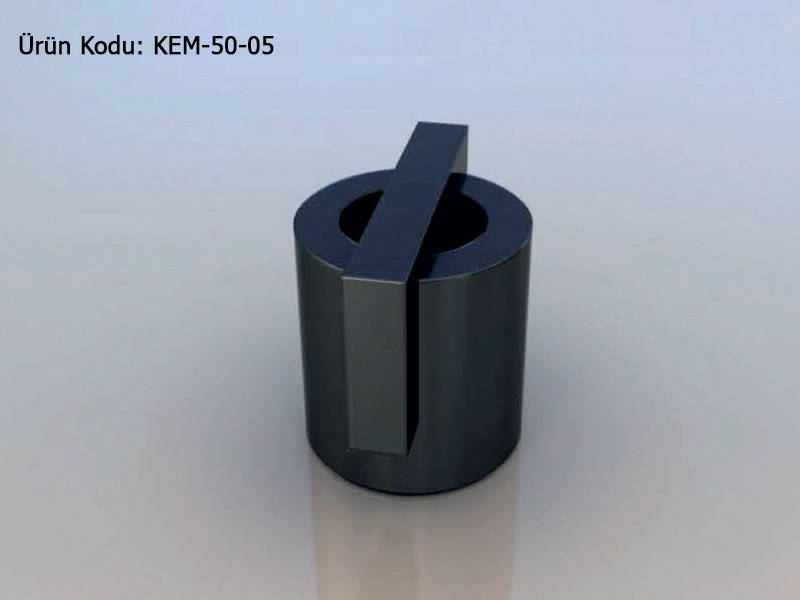

Thanks to its modular structure and easy maintenance, no skilled technicians are needed for parts replacement or calibration. Its compact design allows seamless operation in tight or low-ceiling environments.

Durable, efficient, and cost-effective, DM-KEM 30 is an essential addition to any professional equipment fleet.

| Specification | Value |

|---|---|

| Dimensions | 220 × 85 × 145 cm |

| Gross Weight | 400 kg |

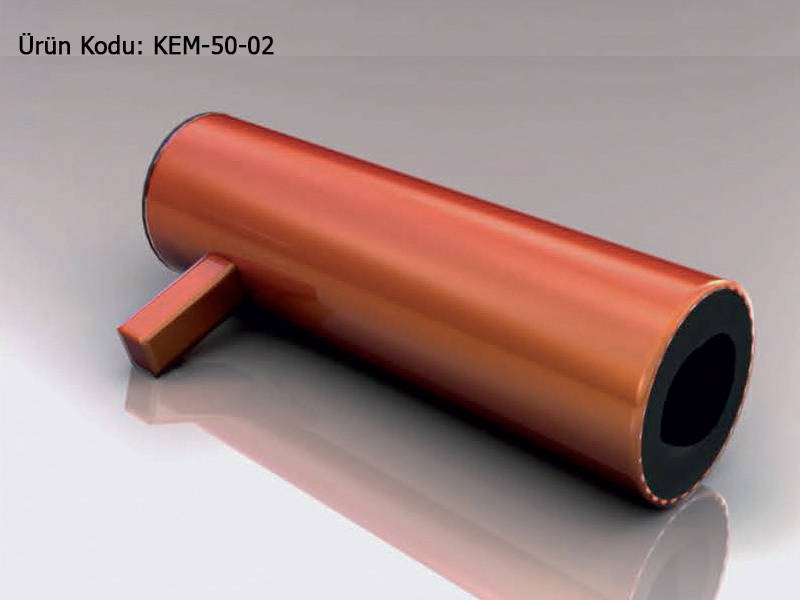

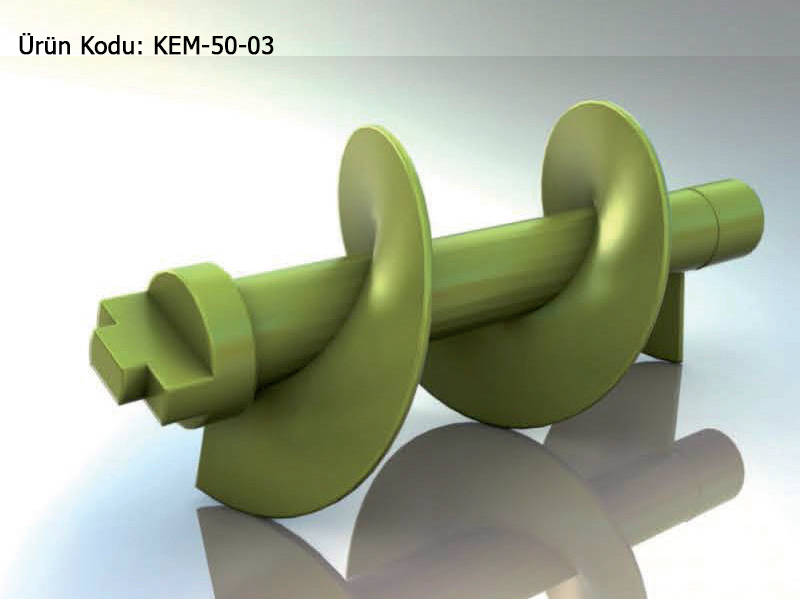

| Rotor Type | P8 |

| Theoretical Pumping Capacity | 70 L/min |

| Maximum Output Pressure | 40 bar |

| Output Hose Diameter | 1 inch |

| Max Delivery Distance (Vertical) | 80 m |

| Max Delivery Distance (Horizontal) | 100 m |

| Main Motor Power | 7.5 kW |

| Mixer Motor Power | 3 kW |

| Voltage / Frequency | 380 V / 50 Hz |

| Total Power Consumption | 10.5 kW |

| Rotor Speed | 407 rpm |

| Mixer Speed | 55 rpm |

| Tank Capacity | 200 liters |

Photo Gallery